Introduction of Die Casting

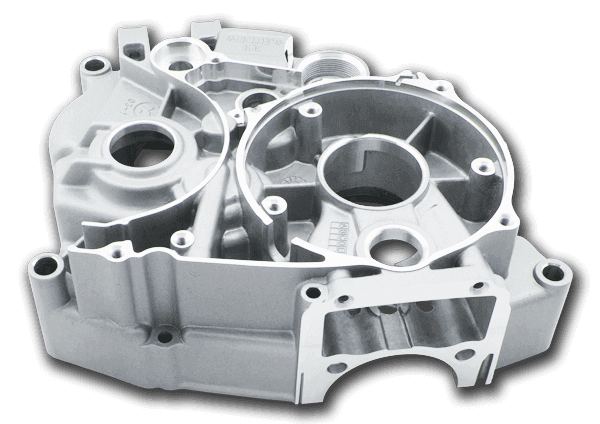

Die casting is an important technology for metal manufacturing in many modern industrial fields. It is used to describe processes that utilize metal dies, or molds, to produce parts from various metals. These processes include gravity permanent mold casting, in which the liquid metal is poured into the die; low-pressure die casting, in which the metal is forced into the mold with air pressure; and high-pressure die casting, in which a hydraulic ram is used to inject the molten metal into the die at extremely high pressures.

This is due in large part to its incredible versatility, as well as its reliability, accuracy, repeatability, and reasonable cost. Die cast parts, which range in complexity from simple doorknobs to transmission housings, can be found virtually everywhere, in everything from toys to aircraft.

What is Die Casting and the Processes

In die casting, there are two different ways of manufacturing components: hot chamber and cold chamber die casting.

The basic die casting process consists of injecting molten metal under high pressure into a steel mold, which is called a die. The process cycle for die casting consists of five main stages, which are explained as below.

- Drawing analysis review of your CAD files.

- Tooling design and make a preparatory work

- Die-casted part making and casting

- Clamping; Injection; Cooling; Ejection and Trimming.

- Doing T1 test for inspection

- Samples production and confirmation

Advantages of Die Casting

- Die casting provides complex metallic shapes within closer tolerances than any other mass production processes.

- In die casting, you can also combine multiple parts into a single part, eliminating assembly operations and lowering labor costs.

- It can be achieved as the whole process is almost completely automated.

Materials of Die Casting

Aluminum: cost effective, lightweight and corrosion and rust resistant with dimensional stability, strength at high temperatures, accepts surface finishes, and conductivity as well as long lasting and durable.

Zinc: easiest to cut, high ductility, impact strength and can easily be plated.

Application of Die Casting

Die casting is mainly used for large series production. Industrial products made of this method have come to the fold in almost every area. Here is a list of what area could it cover.

- Aerospace

- Automotive industry

- Household

- Electronics

- Machinery

- Lighting Technology

Prototypes and Parts Delivered Fast with 4 Simple Steps

Upload 3D Files

To start your project, simply fill in a few information and upload the 3D files.

Quote & Design Analysis

You'll receive a quote shortly, and we'll send you design for manufacturability (DFM) analysis if necessary.

Order Confirmation

Once you review the quote and place your order, we'll start the manufacturing process. We also offer finishing options.

Parts are Shipped!

Your prototypes or custom manufactured parts will be inspected and delivered straight to your doorstep.