3D Printing Services

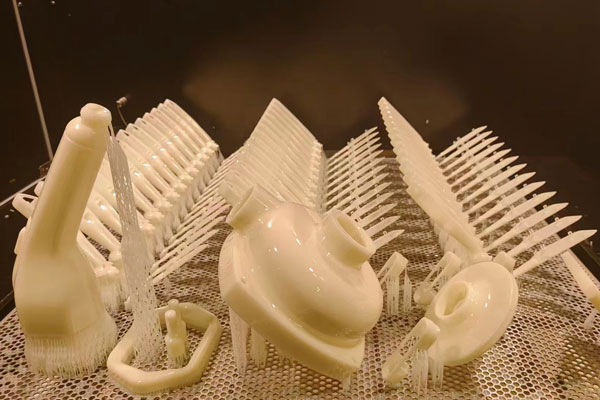

In the manufacturing industry, most customers must be amazed about the great process of 3D printing that brings to us. 3D printing is spurring breakthroughs in many industries. It can be said it perfectly combine with our daily life. 3D printing covers a host of processes and technologies that offer a full spectrum of capabilities for the parts and products in different materials.

It shows a huge potential for the customers and manufacturers that it could make parts and products in a fast delivery time and reduce the risk of waste cost. This kind of manufacturing method has become a hottest option while manufacturing products.

What is 3D printing?

3D printing, also called additive manufacturing, is a process for making a physical object from a three-dimensional digital model, typically by laying down many successive thin layers of a material. It brings a digital object (its CAD representation) into its physical form by adding layer by layer of materials.

In recent years, its widespread use in manufacturing has grown a lot. It could perfectly avoid the limitations to traditional manufacturing, like reducing the reliance on human labor. It enables to encourage and drive innovation with unprecedented design freedom.

Processes of 3D printing

- SLA

SLA is a method of creating 3D objects using a light-emitting device (laser or digital light processing) that illuminates and cures a liquid photopolymer resin (thermosetting plastic) layer by layer. SLA has the ability to produce fine features and provide good surface finish with minimum stair stepping effect.

- SLS

Stereolithography (SL) uses a setup similar to SLS, it, a computer-assisted laser source over a platform. In SL, though, the laser is used to induce curing of a liquid layer of polymer resin via photopolymerization.

Benefits of 3D printing

- Inventors and designers can build and test prototypes of new products quickly and cheaply.

- It could reduce more risks that are created by human labor. A machine can’t get tired, which leads to overall improved safety.

- The speed of the manufacturing production will be increased.

Materials of 3D Printing

The materials available for 3D printing have come a long way. There is a wide variety type.

- Metal

One of the strongest and most commonly used metals is stainless steel. Besides, gold, silver, aluminum and titanium etc. could be used as materials for 3D printing.

- Plastic

Nylon is commonly used in powder form with the sintering process or in filament form with the FDM process. It is a strong, flexible and durable plastic material that has proved reliable for 3D printing. ABS also can be used in 3D printing.

Applications of 3D Printing

- Prototypes: fast production, free design and efficient creation.

- Medical: make it far easier to reproduce, last longer time.

- Aerospace: precise parts and efficient, and free design.

The Future of 3D Printing

The future of 3D printing is very promising and exciting. According to various sources, 3D printing has the potential to transform many fields and industries, such as aerospace, health care, construction, and more.

Prototypes and Parts Delivered Fast with 4 Simple Steps

Upload 3D Files

To start your project, simply fill in a few information and upload the 3D files.

Quote & Design Analysis

You'll receive a quote shortly, and we'll send you design for manufacturability (DFM) analysis if necessary.

Order Confirmation

Once you review the quote and place your order, we'll start the manufacturing process. We also offer finishing options.

Parts are Shipped!

Your prototypes or custom manufactured parts will be inspected and delivered straight to your doorstep.