What is CNC Machining ?

CNC machining is seen by many as a vital element to the core production of manufacturing. CNC stands for computer numerical control. These complex machines are tools like mills that are guided by computer instructions. It provides a level of efficiency and accuracy of the parts that why this machining way would be hit in the manufacturing industry.

There are quite a lot CNC machines which have different constructions. Due to these machines, manufacturers can produce parts in less time, reduce waste and increase the rate of correct.

CNC Prototype

It is vital to make a CNC prototype before the part is officially put into production. It helps to confirm the design assessment, functionality testing, quality assurance and enhancement. A CNC prototype gets every detail right, powered by a computer’s precise abilities.

CNC Low Volume

CNC low volume production can be an effective solution for business that require a reduced number of customized manufactured parts. It could run quickly get out of hand if the customers don’t take care during the design process. It is the fast way to see the parts in a short delivery time.

Mass Production

CNC machining allows for better time management, less waste of resources and lower maintenance requirements. For mass production, CNC machining would be a best option because of its precision and accuracy. It would really save time, eliminate human error and fast delivery of products.

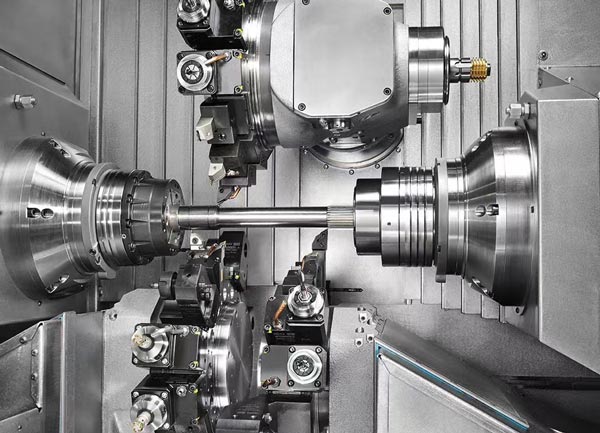

CNC Turning

CNC Turning is a specific type of CNC Machining, referring to the particular subtractive machining process. It can be completed on the outside and inside of a part. In general, CNC turning tends to produce parts faster and more affordably than milling. Turning has a larger range of motion, so it’s ideal for creating more complex designs, especially in cylindrical parts.

CNC turning is a cost-friendly option if you are mass producing symmetrical parts. CNC lathes are extensively used to produce parts at a much higher rate and lower cost per unit.

CNC Milling

CNC milling is one of the most popular and common use mechanical process in CNC machining. It removes material from the workpiece to create a finished product as customer requested. The operations that take place on the workpiece using this tool provide solutions to many different needs in the manufacturing field.

Compared with the traditional machining way. It reduces the need for human labor and the human error. Meanwhile, it increases mass production potentials. Parts would be made with speed and accuracy through this method. Milling machines make the process much faster, easier and safer.

Prototypes and Parts Delivered Fast with 4 Simple Steps

Upload 3D Files

To start your project, simply fill in a few information and upload the 3D files.

Quote & Design Analysis

You'll receive a quote shortly, and we'll send you design for manufacturability (DFM) analysis if necessary.

Order Confirmation

Once you review the quote and place your order, we'll start the manufacturing process. We also offer finishing options.

Parts are Shipped!

Your prototypes or custom manufactured parts will be inspected and delivered straight to your doorstep.