What is Rapid Tooling?

Rapid tooling (RT) is a manufacturing method that enables one to product a tool, part or product quickly. It produces parts combining conventional tools with rapid prototyping techniques. It becomes the hottest option for low volume production. It gets specially designed to streamline the mold structure fast and affordably.

Rapid tooling techniques can be divided into two categories: indirect rapid tooling and direct rapid tooling. Many different companies worldwide are actively pursuing RT approaches and eliminating or decreasing limitations.

What rapid tooling services can we provide?

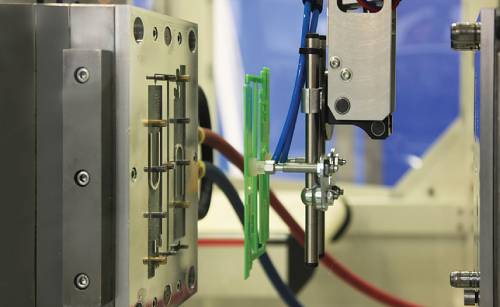

Plastic Injection Mold

Plastic injection molding uses in the mass fabrication of plastic parts. It involves melting plastic pellets (thermosetting/thermoplastic polymers) that, once flexible enough, are injected at pressure into a mold cavity, filling it and solidifying it to create the finished product.

It is ideal for manufacturing high volumes of plastic products, which serves quite a lot of industries and individuals. Injection molding is referred as a highly productive and efficient method in fabricating plastic ones. It can produce identical parts consistently.

Die Casting Mold

Die casting is a metal casting process in which molten metal is forced into a steel mold under high pressure into a mold cavity. The whole process consists of five steps: clamping, injection, cooling, ejection and trimming.

Although die-casted parts involve higher initial costs compared to other casting methods, it affects to result in lower per-unit costs for high volume production. Using die casting helps to think of it as a method of conversion or a way of turning one thing to another.

Compression Mold

Compression molding is a composite manufacturing process normally used to produce composite components in high volume production like automotive parts. It is a mold type in which a charge of material is squeezed into shape by compressive force.

It is widely used, simple and flexible method of fabrication. During the production time, it shows greater reproducibility and lesser cycle time. This technique uses hot matched metal die with a vertical hot and cold press arrangement for compressing the materials.

Materials for Rapid Tooling

Aluminum 7075

Aluminum 7075 is a typical member of metals. It is widely used in aerospace as essential load-bearing structures. It can be heat-treated to achieve strengths comparable to many steel alloys while maintaining a moderately formable quality in the soft, annealed temper. This material has ideal and desirable specific strength, rigidity, good machinability, and excellent corrosion resistance.

P20

The most popular semi-hardened tool steel, P20, can handle volumes of up to 50,000. It is renowned for being trustworthy with all-purpose and abrasive resins containing glass fibers. Because P20 is more affordable and durable than aluminum in various applications, it gets used by many engineers and product designers. Larger pieces that indicate heavier shot weights have higher injection and clamping pressure tolerances. P20 also welds well and works well as a machine material.

SI364 and NAK80

Mold steel called NAK80 is precipitation- or age-hardened, and it has a uniform through the hardness of about 40 HRC. The steel has massive dimensional stability, a consistent grain structure, and uniform hardness. It is also too clean. NAK80 tool steel is an upgraded version of NAK55 in terms of toughness, EDM surface, and mirror surface.

Prototypes and Parts Delivered Fast with 4 Simple Steps

Upload 3D Files

To start your project, simply fill in a few information and upload the 3D files.

Quote & Design Analysis

You'll receive a quote shortly, and we'll send you design for manufacturability (DFM) analysis if necessary.

Order Confirmation

Once you review the quote and place your order, we'll start the manufacturing process. We also offer finishing options.

Parts are Shipped!

Your prototypes or custom manufactured parts will be inspected and delivered straight to your doorstep.