CNC Automotive Parts Services in GM

Productivity understands that change can be both overwhelming and frightening. Early industrial methods were bound by the availability of an energy source with humans being employed for more precise activities. With the development of manufacturing, more people prefer to be highly automated on CNC machining.

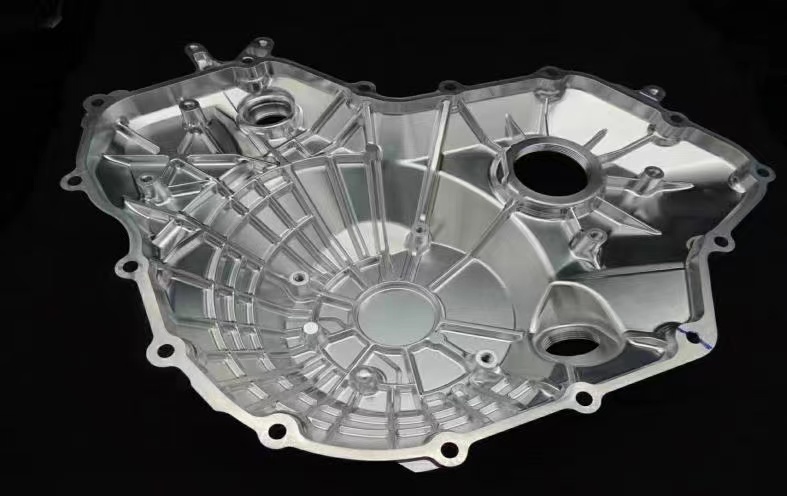

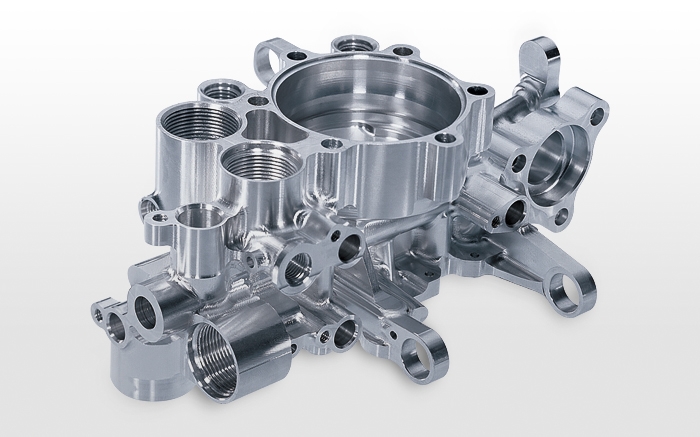

There are several ways to carry out like cutting, drilling and other industrial procedures. We are able to find out the most correct methods to make products. Check out the car parts as below that we have made.

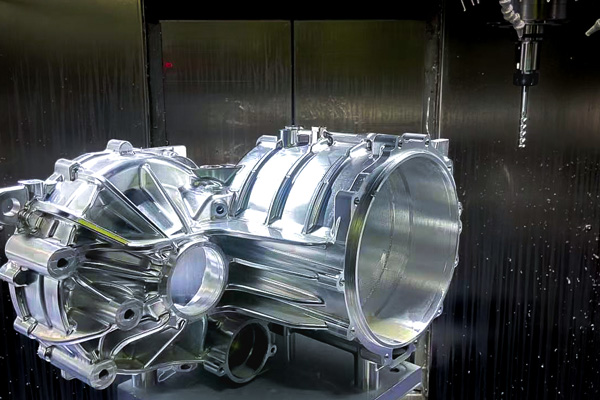

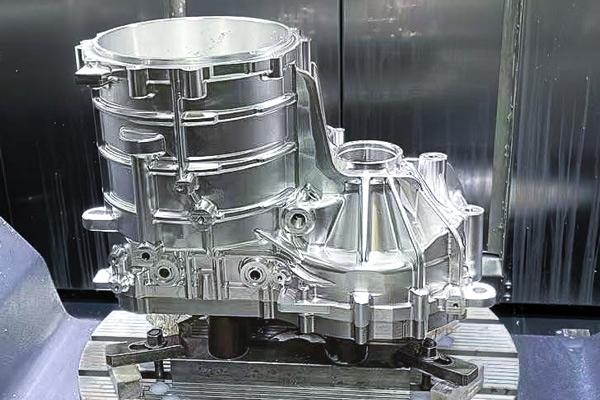

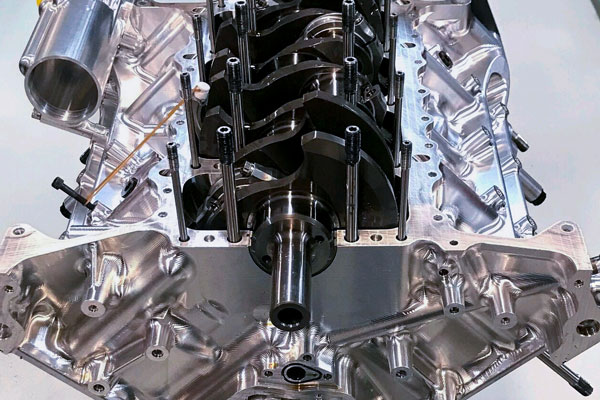

Engines

Combining with the newest CNC machining technology, some critical components of a car’s internal combustion engine may get manufactured using CNC machining. High standard techniques like milling and turning can satisfy both quantities and qualities. Car engine parts have the most stringent and highest demands imaginable for precision.

Interior Panels

Interior panels like dashboard are used in CNC machining. It is precise enough to mill a dashboard frame from a raw plastic block. It guarantees that when the cuts for the speedometer, fuel gauge, and indicator lights get placed, they get aligned.

Drive Axles

Automobile drive shaft is a rotating body with high speed and few supports. It is pretty important to keep balance. The function of it is to transmit the power of the engine to the wheels together with the drive axle. Due to the necessity of accuracy, CNC machining is the right method to make drive axles.

Starter Motors

CNC-machined metal is still finding applications in the automotive industry. CNC machining can produce complex items such as starters. Because of the process’ accuracy and complexity, these components may get optimized.

Lighting

Aluminum can be regarded as the highest usage rate material for lighting. And it is one of the essential uses of CNC machining in the automobile sector. PMMA machining allows producers to create vehicle illumination, including headlights and interior lighting.

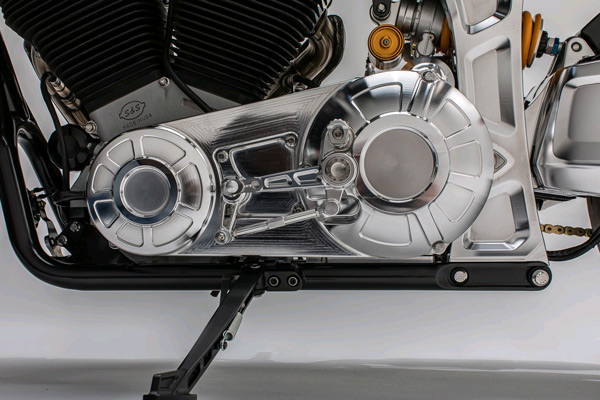

Custom Parts

Use CNC machining by OEMs to create unique components or unusual replacement parts.

CNC Automotive Parts

How to Make Custom Automotive Parts?

1. Bottom up the engineering of the original part.

Using a simple measuring tool, a coordinate measuring machine and a 3D optical scanner to copy the original part which has all the fixtures and base surfaces in common but is more suitable for the cars.

2. Verify the design and put the prototype into production.

Before the mass production, we need to make sure the design is manufacturable. We can put into the production when the design has been taken by engineers. According to the size and precision, a 3D-printed mold can be made as a prototype.

3. Testing the prototype and make custom auto parts by 5 axis CNC machining.

After finishing the prototype mold, a testing should be carried out. Once both sides ensure it works, the prototype can pass the testing. In order to guarantee the quality and precision, 5 axis CNC machining would be a good choice.

CNC Automotive Parts Tolerance We Can Do?

Limit Tolerances

The limit tolerance is the minimum and maximum permitted value for a dimension. For usage in assembly, the relevant dimensions of the produced components must lie between these two positions.

One Side Tolerances:

One side tolerance can be defined as the value range in one way. Under the control of it, we could not employ shafts with diameters more than 70mm. That would result in increased waste and lead time.

Bilateral Tolerances:

A part’s final dimensions might vary on either side of the nominal or actual profile when it has bilateral tolerances. For example, a bilateral tolerance of 30+0.05/-0.05mm denotes a minimum and maximum of 30.05mm and 29.95mm, respectively, with 30mm being the nominal value.

Geometric dimensioning and tolerance:

Geometric dimensioning and tolerance (GD&T) go beyond standard dimensional tolerances. It establishes various features of the dimension, such as concentricity, flatness, and actual position, in addition to guaranteeing that the final value remains inside the stated boundaries. The final dimensioning must contain these established criteria to pass the test.

Advantages of CNC Automotive Parts

Speed

The most significant benefit of CNC Auto Parts Machining is the speed it provides. The production efficiency is much higher in the case of multiple and small batches production. Due to the use of the best cutting amount, it can reduce the time.

Precision and Accuracy

Because of the processing is done automatically by a computer, there is no need to consider human limitations. The guarantee of precision and accuracy is crucial for designing and making car parts.

Customization

CNC machining can assist in making specific parts. This benefit is accompanied by quick delivery times, either as single parts or in modest manufacturing batches.

Automotive Parts In Prototype Or Low Volume

Prototypes and Parts Delivered Fast with 4 Simple Steps

Upload 3D Files

To start your project, simply fill in a few information and upload the 3D files.

Quote & Design Analysis

You'll receive a quote shortly, and we'll send you design for manufacturability (DFM) analysis if necessary.

Order Confirmation

Once you review the quote and place your order, we'll start the manufacturing process. We also offer finishing options.

Parts are Shipped!

Your prototypes or custom manufactured parts will be inspected and delivered straight to your doorstep.