CNC Prototype and Low Volume Production

GM PARTS, one of the leading CNC machining partners, offers a one-stop solution from rapid prototyping to mass production. It aims to provide precise CNC machined parts for global customers, especially in the automotive and automation industry.

GM PARTS has five self-owned factories equipped with more than 200 milling, turning, and mill-turn machines including 50 5-axis machines. GM PARTS is always devoted to offering qualified parts to customers and keeping importing advanced inspection equipment such as ZEISS CMM, HITACHI material tester, optical projector, and height gauge.

GM PARTS is trying to meet all the needs and provide more flexible options for our customers. We also offer extra services for sheet metal, 3D printing, vacuum casting, and molding solution. During the past tens of years, we have served 1000+ customers, manufactured 20,000+ customized products, and shipped to 20+ countries.

All we do is make our customers’ design concepts into reality.

Why Choose GM Parts?

5 self-owned factories

Fast response within 12 hours

High reputation in automotive & automation industry

100+ material available

Provide complete technology and service

ISO-9001, IATF-16949 , ISO-14001 and ISO-45001

GM CNC Prototype Services

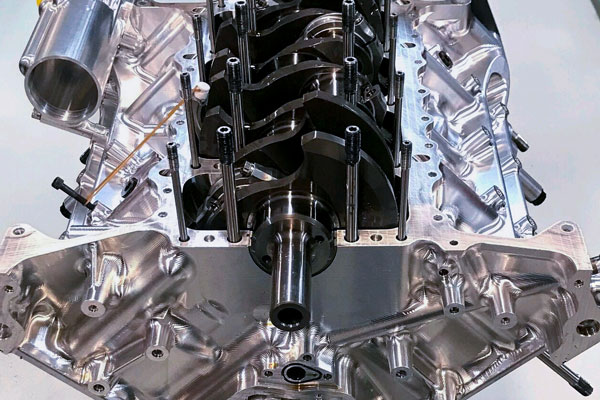

Automotive Parts

CNC machining plays an essential role in the prototyping of automotive industry. Many of the most significant advancements in the automobile sector are direct with manufacturing developments. Car makers may raise production rates more quickly and precisely with computer programs and motorized design tools. Car parts which are made by CNC machining would have better designs and functions.

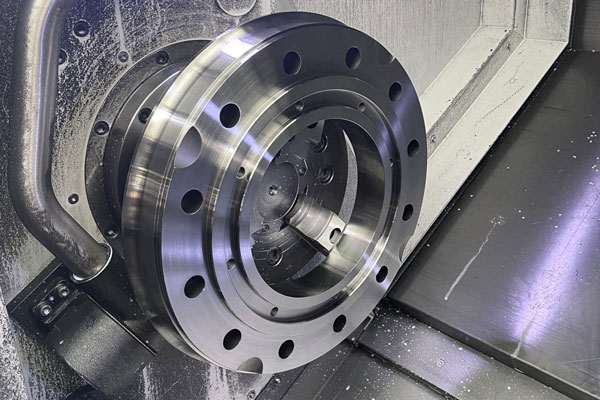

Automation parts

CNC machining in automation is applicable for prototyping and manufacturing parts. CNC Machining is in charge of creating automotive prototypes to exact specifications. CNC prototyping also produces parts for various means of transportation, such as cargo boats and freight trucks. Due to the high precision and quality, there is a growing trend and progress for the usages of automotive parts.

Medical Parts

Medical field is continually developing, and the demand for innovative equipment is expanding. For the medical industry, precision machining can be a matter of life or death. It has a strong mission. There is little space for error, so the prototype must be an accurate and functioning reproduction of the end product. So that CNC machining is the right option for this sector.

CNC Low Volume Production

Low volume production is a rapid method that precedes full scale production. It is common to combine with CNC machining. Easily speaking, it is a simple approach to scale. It does not require investment in tools. However, it not only reduces the risks that whether the parts are validated and shortens the time to market, but also gives more opportunities for clients to save their prototype costs. It is not easy to get a batch of up to 100 pieces promptly, still less to using prototyping.

Nowadays, the cost of low-volume production has decreased thanks to a hybrid strategy that involves conventional and additive manufacturing methods. The entry costs for additive manufacturing are cheap since there is less material waste and labor.

As production time shrinks and new production development shortens, production lines would prefer to choose low volume production for meeting clients’ customization and diversity demands. Flexible effective time to market and available cost savings remain critical.

Low volume production can be an excellent way to avoid spending a large sum of money all at once. Through this method, you can make high-quality items while also receiving excellent manufacturing services. When there is a need to generate value products, the industry owner must create a valuable product for the users, which can result in better profits in low-volume manufacturing. It also satisfies the minimal order criteria of users and has a reduced total cost. Products can be gotten customized to meet specific requirements. Besides, there is less danger of waste.

GM Capabilities Behind Numbers

5-Axis CNC Machines

Companies Served

Years in Business

Parts Made

Shipped Countries

Our Partners

Prototypes and Parts Delivered Fast with 4 Simple Steps

Upload 3D Files

To start your project, simply fill in a few information and upload the 3D files.

Quote & Design Analysis

You'll receive a quote shortly, and we'll send you design for manufacturability (DFM) analysis if necessary.

Order Confirmation

Once you review the quote and place your order, we'll start the manufacturing process. We also offer finishing options.

Parts are Shipped!

Your prototypes or custom manufactured parts will be inspected and delivered straight to your doorstep.